Navigating the Globe of Fasteners and Machining: Techniques for Accuracy and Speed

In the complex world of fasteners and machining, the pursuit for accuracy and rate is a perpetual challenge that demands precise interest to information and strategic planning. From recognizing the diverse variety of bolt types to choosing optimum materials that can stand up to strenuous demands, each action in the procedure plays a critical function in attaining the desired result. Accuracy machining strategies additionally elevate the complexity of this craft, needing a fragile equilibrium in between technological expertise and ingenious methods. As we dive right into the strategies that can enhance both speed and effectiveness in this domain, the interaction in between high quality control actions and functional excellence becomes a vital focal factor.

Understanding Bolt Kind

When choosing fasteners for a job, understanding the different kinds offered is vital for making certain optimal efficiency and reliability. Fasteners can be found in a vast array of types, each developed for specific applications and needs. Bolts are used with nuts to hold products together, while screws are flexible fasteners that can be made use of with or without a nut, relying on the application. Nuts, on the other hand, are inside threaded bolts that friend with bolts or screws, providing a safe and secure hold. Washers are crucial for dispersing the tons of the bolt and protecting against damage to the product being attached. Furthermore, rivets are permanent fasteners that are suitable for applications where disassembly is not needed. Comprehending the distinctions between these bolt types is essential for selecting the right one for the job, making sure that the connection is solid, resilient, and trusted. By choosing the ideal fastener kind, you can optimize the performance and durability of your task - Fasteners and Machining.

Choosing the Right Products

Comprehending the significance of choosing the ideal products is paramount in making sure the optimum efficiency and integrity of the chosen fastener types went over previously. When it pertains to bolts and machining applications, the product selection plays an important duty in establishing the overall strength, resilience, rust resistance, and compatibility with the designated setting. Various products supply varying properties that can significantly impact the performance of the fasteners.

Typical materials made use of for fasteners include steel, stainless steel, titanium, aluminum, and brass, each having its distinct toughness and weaknesses. Steel is renowned for its high toughness and longevity, making it appropriate for a wide array of applications. Selecting the ideal material includes considering aspects such as stamina demands, ecological problems, and budget plan restraints to make sure the preferred performance and longevity of the bolts.

Accuracy Machining Techniques

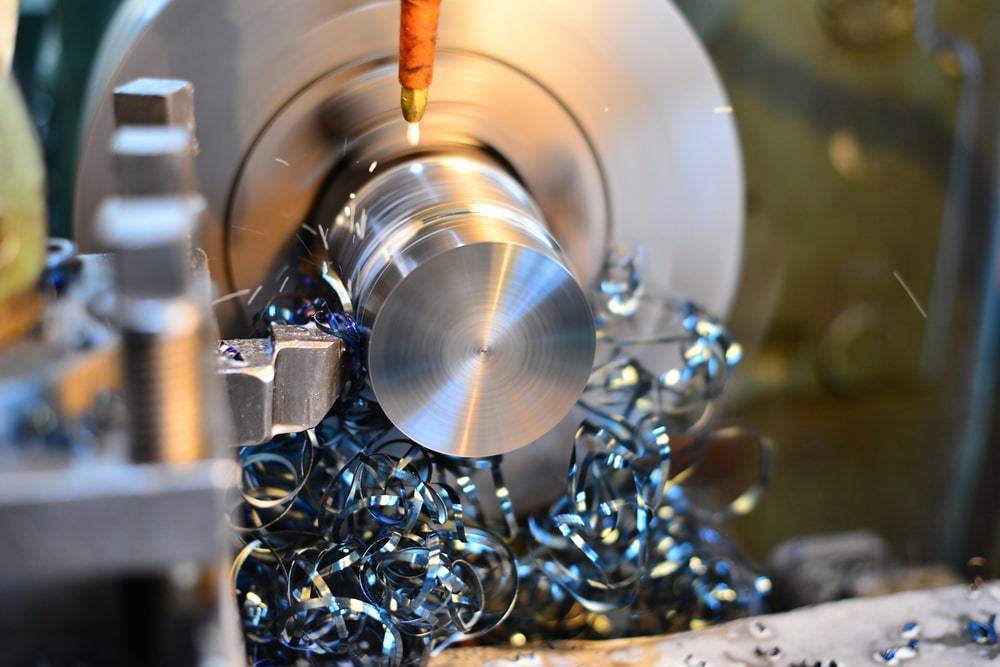

In enhancement to CNC machining, other accuracy strategies like grinding, transforming, milling, and boring play important duties in fastener production. Grinding assists accomplish great surface area coatings and limited dimensional resistances, while transforming is often used to develop visit here round elements with exact sizes. Milling and boring procedures are crucial for shaping and producing holes in fasteners, guaranteeing they meet exact requirements and function properly.

Enhancing Rate and Effectiveness

To maximize fastener production procedures, it is important to enhance procedures and apply effective approaches that complement precision machining techniques. One essential strategy for enhancing rate and effectiveness is the implementation of lean production principles. By minimizing waste and concentrating on constant renovation, lean practices assist maximize and remove traffic jams operations. In addition, investing in automation innovations can significantly boost production speed. Automated systems can manage repeated tasks with accuracy and rate, allowing employees to concentrate on even more complex and value-added tasks. Embracing Click Here Just-In-Time (JIT) inventory monitoring can likewise enhance effectiveness by ensuring that the appropriate materials are available at the appropriate time, decreasing excess stock and reducing preparations. Fostering a culture of collaboration and communication among team members can enhance overall performance by advertising openness, analytical, and innovation. By incorporating these approaches, suppliers can attain a balance in between speed and accuracy, inevitably enhancing their one-upmanship in the bolt sector.

Quality Assurance Steps

Applying strenuous quality control actions is crucial in making sure the dependability and uniformity of fastener items in the manufacturing process. Fasteners and Machining. Quality control steps incorporate numerous phases, starting from the choice of raw products to the last assessment of the completed fasteners. This involves evaluating aspects such as product stamina, sturdiness, and make-up to assure that the bolts satisfy sector requirements.

Normal calibration of equipment and equipment is important to keep uniformity in manufacturing and make certain that fasteners meet the required tolerances. Applying strict protocols for determining and attending to non-conformities or issues is important in protecting against substandard items from getting in the marketplace. By establishing a comprehensive quality control framework, suppliers can support the reputation of their brand and deliver fasteners that meet the highest requirements of performance and longevity.

Conclusion

In the detailed realm of bolts and machining, the quest for accuracy and speed is a continuous obstacle that requires thorough focus to detail and calculated planning. When it comes to bolts and machining applications, the product choice plays a crucial duty in identifying the general toughness, resilience, deterioration resistance, and compatibility with the intended environment. Precision machining involves numerous innovative approaches that guarantee the limited resistances and requirements needed for bolts.In enhancement to CNC machining, other precision methods like grinding, transforming, milling, and boring play essential functions in bolt manufacturing.To enhance bolt manufacturing processes, it is vital to enhance operations and execute reliable strategies that match precision machining methods.